11.1: Introduction

- Page ID

- 38708

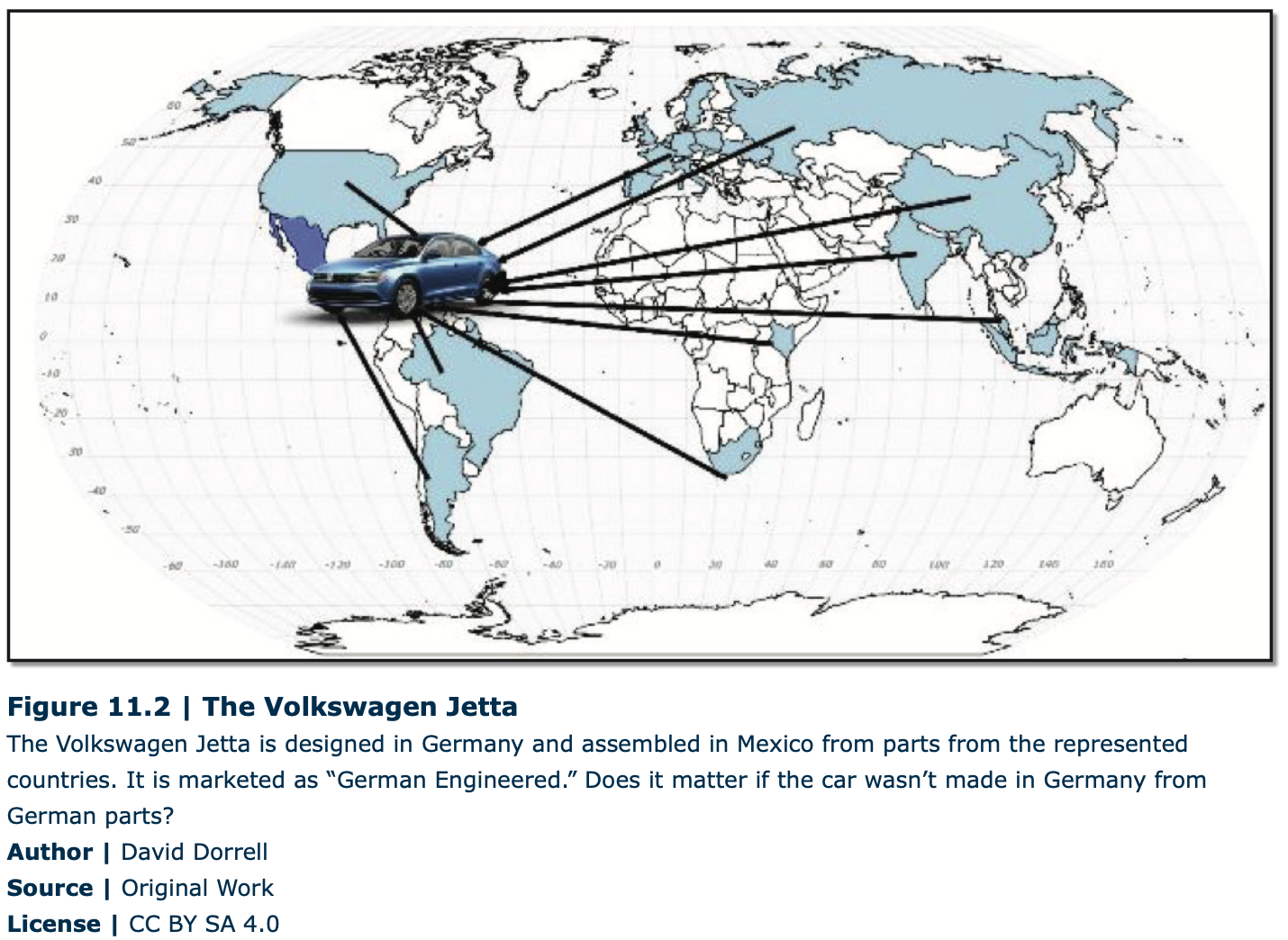

We live in a globalized world. Products are designed in one place, assembled in another from parts produced in multiple other places. These products are marketed nearly everywhere. Until a few decades ago, such a process would have been impossible. Two hundred years ago, such an idea would have been beyond comprehension. What happened to change the world in such a way. What eventually tied all the economies of the world into a global economy? Industry did. The Industrial Revolution changed the world as much as the Agricultural Revolution. Industry has made the modern lifestyle possible.

During the 2016 U.S. presidential election, something very peculiar happened. Candidates from both major parties (Donald Trump and Hillary Clinton) agreed over and over again on one thing (and only one thing). The U.S. needed to create and/or bring back manufacturing jobs. Both candidates promised, if elected, to create new, well-paid manufacturing jobs. This was an odd shift, because for the previous 40+ years Republicans typically embraced free trade that allows manufacturers to choose where and what to produce (and many chose to move operations outside of the U.S.), while Democrats claimed to be working for the interests of blue-collar, working class people, whose jobs and wages had diminished since the 1980s period of de-industrialization both in the U.S. and throughout the developed/industrialized world. In the U.S. manufacturing provided jobs to 13 million workers in 1950, rising to 20 million in 1980 but by 2017 that number was back to 12 million – similar to levels last seen in 1941. A similar story can be found in Great Britain where jobs in manufacturing in 2017 were half of what they were in 1978 and output that once was 30% of GDP accounts for only 10% in 2017. Similar stories can be found in Germany, Japan, and other ‘industrialized’ economies. You may ask yourself, “Where did all of those jobs go?” But if you think about it, you can probably come up with your own answers.

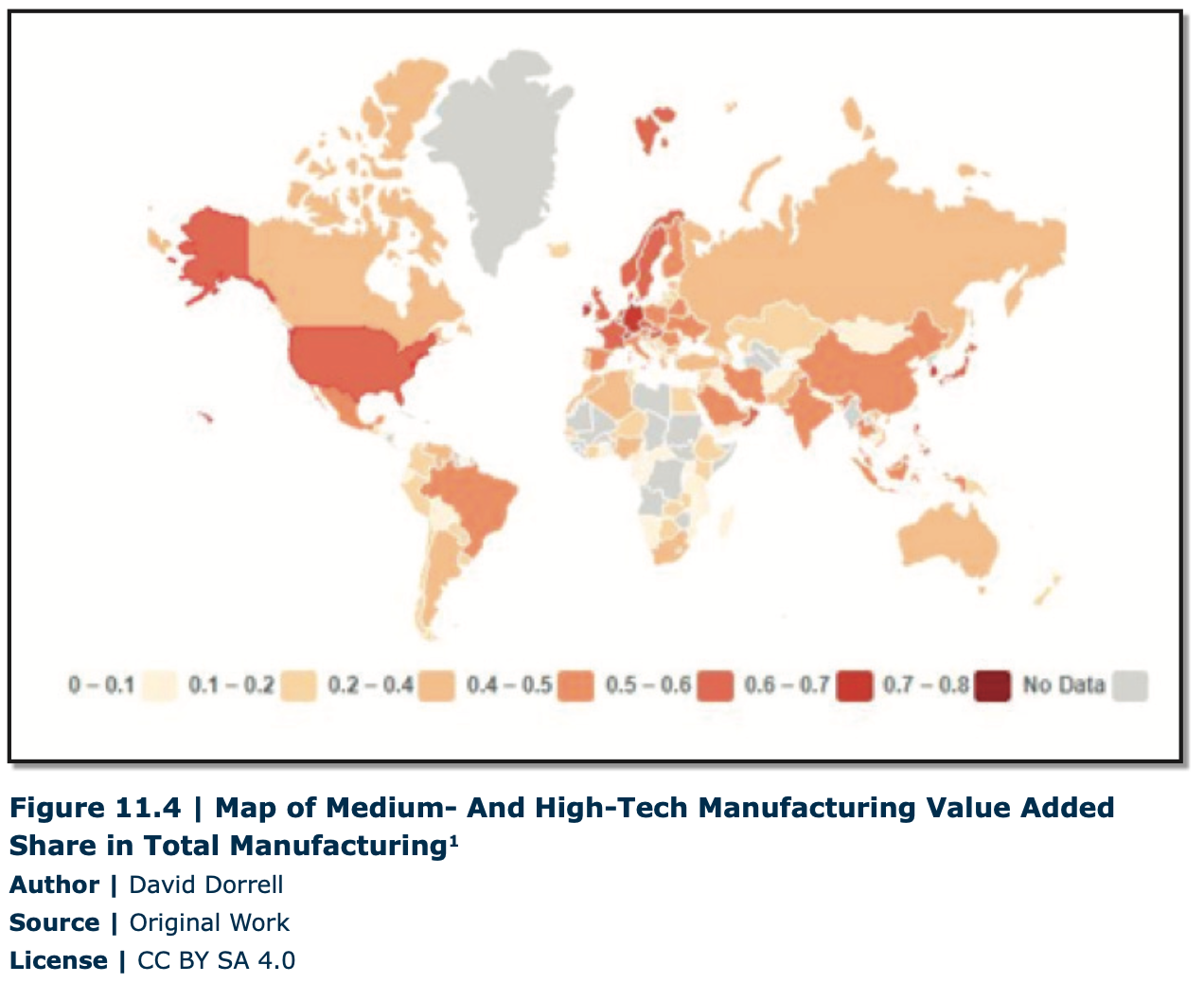

It’s important to note that even as jobs declined, manufacturing output in most industrialized countries continued to increase, so fewer people were producing more things. The first and simplest explanation for this is automation. For years, science fiction writers have warned us that the robots are coming. In the case of manufacturing technology...they’re already here! Workers today are aided by software, robots, and sophisticated tools that have simply replaced millions of workers. Working at a manufacturing facility is no longer simply a labor-intensive effort, but one that requires extensive training, knowledge, and willingness to learn new technologies all the time. The second explanation is the relocation of manufacturing from wealthy countries to poorer ones because of lower wages in the latter.

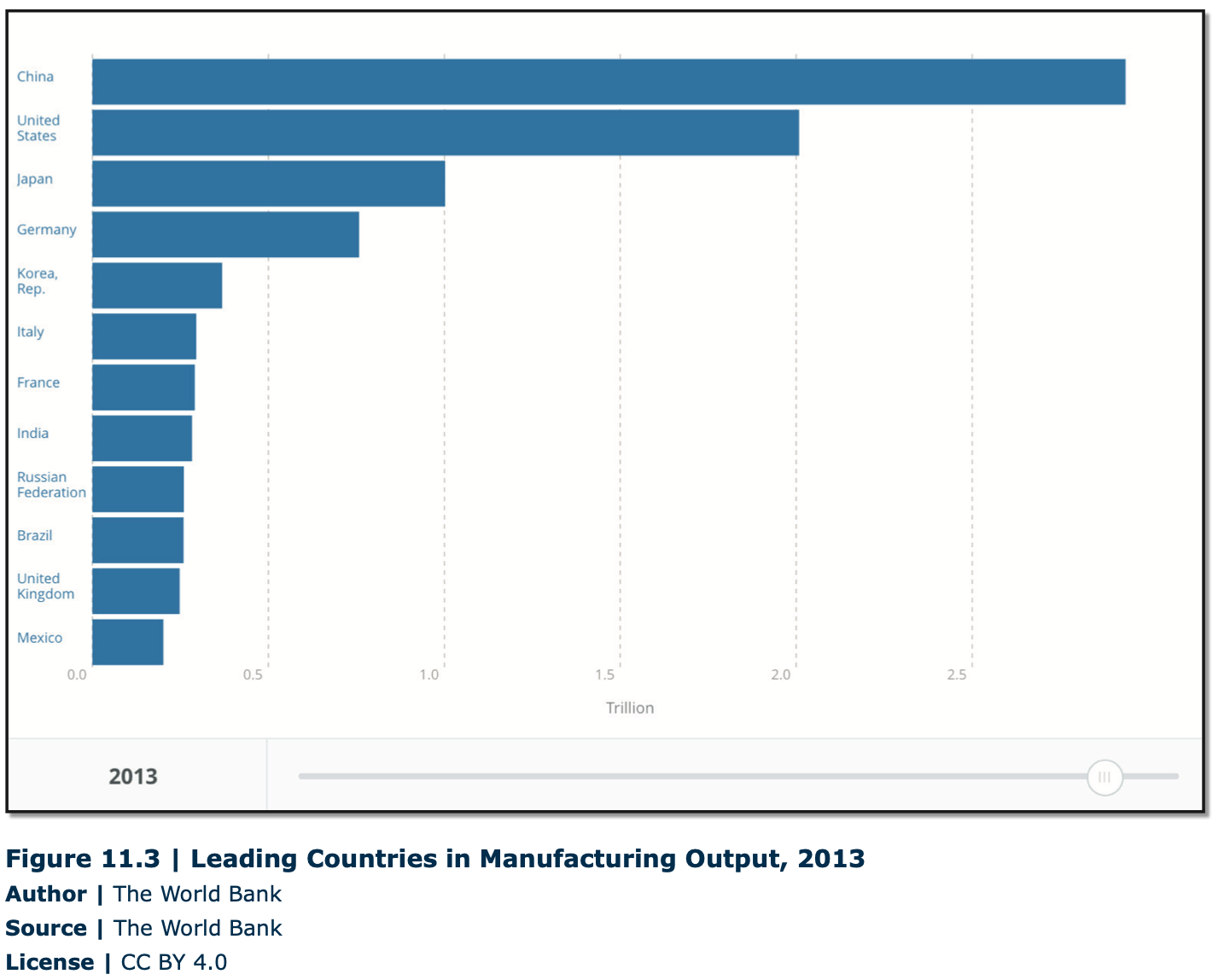

As discussed earlier in this chapter, most countries have moved away from the protectionist model of development, allowing corporations to choose for themselves the location of production. No better example of this shift can be found than Walmart, which in the 1970’s advertised that the majority of all of the products it sold were made in the USA. Thirty years later, it would be difficult for to find ANY manufactured product that was still ‘made in the USA’. A third reason for the decline in manufacturing jobs is a decrease in demand for certain types of items. Steel production in the U.S. and England dropped precipitously during the period of deindustrialization (since the 1980’s) not just due to automation or cheaper wages elsewhere, but also because demand for steel also declined. During the 20th century the U.S., Europe, and Japan required enormous amounts of steel in the construction of bridges, dams, railroad, skyscrapers, and even automobiles. Building of such items in the 21st century has slowed down, not because those countries are in decline, but because there is a limit as to how many bridges and skyscrapers are needed in any country! Demand for steel in a country diminishes as GDP per capita reaches about $20,000. Meanwhile, demand for steel will continue to rise in Japan and India for several years as they (and other industrializing countries) continue to expand cities, rail lines, and other large-scale construction projects. Such a decline in steel production does NOT mean that a country is in decline, but rather that there has been a shift in the type of manufacturing that occurs. The U.S., Germany, and Japan all continue to increase manufacturing output (Figure 11.3), even as their share of global output continues to decline.

Another significant shift in manufacturing relates specifically to the geography of production and is best understood in the consideration of 2 different modes of production: 1) Fordism 2) Post-Fordism. Fordism is associated with the assembly line style of production credited to Henry Ford, who dramatically improved efficiency by instituting assembly line techniques to specialize/simplify jobs, standardize parts, reduce production errors, and keep wages high. Those techniques drove massive growth in manufacturing output throughout most of the 20th century and brought the cost of goods down to levels affordable by the masses. Nearly all of the automobile assembly plants located in and around the Great Lakes region of North America adopted the same strategies, which also provided healthy amounts of competition and new innovation for decades, as North America became the world’s leading producer of automobiles. Post-Fordism begins to take hold in the 1980’s as a new, global mode of production that seeks to relocate various components of production across multiple places, regions, and countries. Under Fordism, the entire unit would be produced locally, while Post-Fordism seeks the lowest cost location for every different component, no matter where that might be. Consider an optical, wireless mouse for a moment. The optical component may come from Korea, the rubber cord from Thailand, the plastic from Taiwan, and the patent from the U.S. Meanwhile, all of those items are most likely transported to China, where low-wage workers manually assemble the finished project and an automated packing system boxes and wraps it for shipping to all corners of the world. Global trade has been occurring for hundreds of years, dating back to the days of the Silk Road, Marco Polo, and the Dutch East India Company, but Post- Fordism, in which a single item is comprised of multiple layers of manufacturing from multiple places around the world, is a very recent innovation. The system has reconfigured the globe, such that manufacturers are constantly searching for new locations of cheap production. Consumers tend to benefit greatly from the system in that even poor middle school students in the U.S. can somehow afford to own a pocket computer (smart phone) that is more powerful than the most advanced computer system in the world from the previous generation. This is kind of a miracle. On the other hand, manufacturing jobs that once were a pathway to upward economic mobility, no longer assure people of such a decent standard of living as they once did.

11.1.1 History of Industrialization

Industrialization was not a process that emerged, fully-formed in England in the eighteenth century. It was the result of centuries of incremental developments that were assembled and deployed in the 18th century. Early industrialization involved using water power to run giant looms that produced cloth at a very low cost. This early manufacturing didn’t use coal and belch smoke into the sky, but it initiated an industrial mindset. Costs could be reduced by relying on inanimate power (first water, then steam, then electricity), converting production to simple steps that cheap low-skilled laborers could do (Taylorism), getting larger and concentrated in an area (economy of scale), and cranking out large numbers of the same thing (Fordism). This is industry in a nutshell. The advantage of industry was that a company could sell a cheaper product, but at a greater profit.

As this mindset was applied to other goods, and then services, the world was changed forever. Places which had been producing goods for millennia suddenly (really suddenly) found themselves competing with a product that was far cheaper. Economist Joseph Schumpeter coined the term “creative destruction” to describe the process in which new industries destroy old ones. Hand production of goods for the masses began to decline precipitously. They quickly became too expensive in comparison to manufactured goods. Today, hand produced goods are often reserved for the wealthy.

A contemporary example of the industrial mode of production is fast food. Looking inside the kitchen of a fast food restaurant will reveal industrially prepared ingredients prepared just in time for sale to a customer. It is not the same process that you would use at home.

In the abstract, companies do not exist to provide jobs or even to make things. Companies exist to produce a profit. If changing the method of making a profit is necessary, then the company will do that in order to survive. If it cannot, then it will go away. For example, many companies today are highly diversified, for example Mitsubishi produces such unrelated products as cars and tuna fish. What is the connection between the two. They both produce profit.

11.1.2 Industrial Geography

How is industry related to geography? For one thing, industrial societies have more goods in them. Since the goods are cheaper, people just have more things. For another, the means of production, the factories, shipping terminals, and distribution centers are visible for anyone to see. The lifestyles of industrialized people are different. Pre-industrialized societies are not regulated by clocks, for example, people wear lass-produced similar clothing. They listen to globally marketed music. If it seems like you already read this in the chapter on pop culture, you have. Pop culture is a function of industry. Geography is concerned with places and industry changed the way the world operates. It changed the relationships between places. Places that industrialized early gained the ability to economically and politically dominate other parts of the world that had not industrialized. Something as simple as having access to cheap, mass produced guns had impacts far beyond mere trade relationships.

Over time industrial production changed from one that disrupted local economies to one that completely changed the relationship that most human beings had with their material culture, their environment, and with one another. Industry has improved standards of living and increased food production on one hand and it has despoiled environments and promoted massive inequality on the other.

Industrialization is about applying rational thought to production of goods. Specifically, this form of rational thought refers to discovering ways to reduce unnecessary labor, materials, capital (money), and time. In the same way thatfactories changed how things were produced, it also changed where things were produced. Locational criteria are used to determine where a factory even gets built.